The Kenworth T800 is known for durability but can require costly repairs due to complexity. Maintenance is essential for efficiency and safety. This article covers T800 issues and maintenance tips.

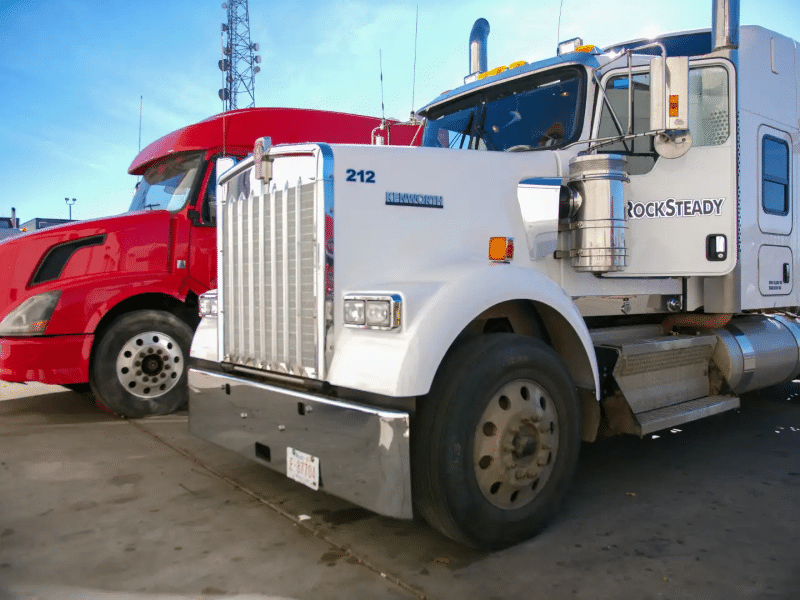

The Kenworth T800 is an iconic heavyweight in the heavy-duty truck industry, renowned for its exceptional durability and reliability. Manufactured by Kenworth, a subsidiary of PACCAR, the T800 has earned its reputation as a workhorse on the highways and construction sites of North America and beyond. These trucks are purpose-built to tackle the most demanding tasks, from long-haul freight transport to heavy equipment hauling and construction site operations.

One of the most critical challenges faced by owners and operators of heavy-duty trucks, including the Kenworth T800, is the potential for costly repairs. These vehicles are complex machines with numerous intricate components, and when these components fail, it can lead to substantial repair bills. Plus, unexpected breakdowns can result in downtime, lost revenue, and compromised safety on the road.

Caring for these trucks and implementing effective maintenance practices is not just a matter of fiscal responsibility but also a safety imperative. A well-maintained Kenworth T800 is not only more cost-effective but also safer for its driver and others sharing the road. This article explores the common repair issues that Kenworth T800 trucks may encounter and provides valuable insights into strategies for preventing these costly repairs, ultimately helping owners and operators maximize the lifespan and efficiency of their heavy-duty assets.

Common Costly Repairs in Kenworth T800 Trucks

Despite the Kenworth T800’s reliability, it’s still prone to significant wear and tear due to its heavy loads, long hours on the road, and exposure to harsh environmental conditions.

Engine Issues

The engine is the heart of any heavy-duty truck, including the Kenworth T800. It provides the power needed to haul heavy loads over long distances. However, engine issues can be some of the most costly and disruptive repairs in these trucks.

Engine problems can arise from a variety of factors, including poor maintenance practices, overloading, fuel quality issues, and extreme operating conditions. When left unaddressed, engine issues can lead to reduced fuel efficiency, loss of power, and even complete engine failure. The consequences? A malfunctioning engine extends beyond repair costs; it includes downtime, missed deliveries, and potential safety hazards on the road.

In the event of engine damage, repairing or replacing a heavy-duty truck engine can be a significant financial burden. Costs can range from thousands to tens of thousands of dollars, depending on the extent of the damage and whether you choose to rebuild or replace the engine.

Transmission Problems

The transmission system in a Kenworth T800 is responsible for transferring power from the engine to the wheels and ensuring the truck can move smoothly through its gears. Transmission issues can severely impact a truck’s performance, leading to a drop in fuel efficiency, slipping gears, rough shifting, or even complete transmission failure.

Often a culprit of wear and tear, improper maintenance, or harsh driving conditions, a damaged transmission calls for an expensive fix — either reparations or replacements. Costs can vary based on the type of transmission, the extent of damage, and whether you opt for a new or rebuilt unit.

Suspension and Chassis Problems

The suspension and chassis of a Kenworth T800 play a crucial role in providing stability and a smooth ride, especially when dealing with heavy loads and rough road conditions. Components like leaf springs, shocks, and bushings can wear out over time due to the truck’s constant exposure to heavy loads and road vibrations.

Failing to address suspension and chassis issues can result in increased wear on tires, reduced driver comfort, and compromised safety. Moreover, ignoring these problems can lead to more expensive repairs down the line, as the added stress on other components can cause them to fail prematurely.

Electrical System Failures

The electrical system in a Kenworth T800 is the brain of its operation, controlling everything from lighting to engine management. When the electrical system fails, it can lead to a host of issues.

Common electrical problems include faulty wiring, blown fuses, malfunctioning sensors, and issues with the truck’s electronic control modules (ECMs). These problems can arise from wear and tear, exposure to the elements, or issues related to the truck’s electrical connections. While electrical system repairs may not always be as expensive as engine or transmission repairs, they can still add up, especially if multiple components require replacement or if diagnosing the issue proves challenging.

Cooling System Failures

The cooling system in a Kenworth T800 is responsible for regulating engine temperature, preventing overheating, and ensuring optimal engine performance. When the cooling system fails, it can lead to, most prominently, engine damage.

Repairing the cooling system involves diagnosing the root cause of overheating and replacing or repairing the damaged components. Costs can vary depending on the extent of the damage, but it’s essential to address cooling system issues promptly to prevent more severe engine damage and costly repairs.

Maintenance Strategies to Prevent Costly Repairs

To get the most out of your Kenworth T800, no matter if it’s a Kenworth T800 day cab or sleeper model, follow the strategies below:

Strategy #1: Regular Servicing and Inspections

Preventive maintenance is the cornerstone of avoiding costly repairs in Kenworth heavy haul trucks. Scheduled servicing and inspections are essential to catch minor issues before they escalate into major problems, as they ensure that all components of the truck are in optimal condition, reducing the risk of unexpected breakdowns.

Strategy #2: Fluid Checks and Replacements

Proper fluid maintenance is vital for the longevity of Kenworth T800 trucks. Engine oil, transmission fluid, coolant, and other fluids play crucial roles in lubricating, cooling, and protecting various components. By regularly checking and replacing these fluids, you can prevent wear and damage to critical systems in your truck.

Driver Education and Awareness

Drivers are often the first to notice issues with the truck while on the road, which is why it’s wise to provide driver education and training on recognizing early signs of problems. Drivers should be encouraged to report any unusual noises, warning lights, or changes in vehicle performance promptly.

Furthermore, encouraging drivers to adopt a fuel-efficient and gentle driving style not only extends the life of the truck but also reduces fuel consumption.

OEM Parts and Components

When it comes to replacements and repairs, opting for genuine Original Equipment Manufacturer (OEM) parts and components is highly recommended. OEM parts are designed specifically for Kenworth trucks, ensuring a perfect fit and compatibility with existing systems, and they are also typically covered by warranties, providing peace of mind. When maintenance practices don’t do the trick, ensure you visit a Kenworth truck repair specialist that offers OEM replacement parts.

While aftermarket parts may be cheaper upfront, they can pose risks in terms of quality and compatibility. They may not meet the same stringent standards as OEM parts, potentially leading to subpar performance or even damage to the truck.

Keeping Detailed Maintenance Records

Maintaining detailed maintenance records is essential for tracking the health of a Kenworth T800 truck. These records provide a historical perspective on all maintenance activities, repairs, and component replacements while also being invaluable for warranty claims and resale value.

With advancements in technology, many fleet management systems and software applications are available for streamlining maintenance record-keeping. These tools make it easier to schedule and track maintenance tasks, document repairs, and monitor the overall health of the fleet. Such systems can save time and improve the accuracy of maintenance records.

Final Words

Proactive maintenance is the linchpin of cost avoidance in the heavy-duty trucking world. Regular servicing, thorough inspections, and adherence to recommended maintenance schedules are vital in catching and addressing issues before they escalate. By adopting responsible driving habits and educating drivers to detect early signs of problems, fleets can significantly reduce the risk of breakdowns and associated repair costs.

We encourage all Kenworth T800 truck owners, whether they manage a single truck or an entire fleet, to make maintenance a top priority. While it may seem tempting to cut corners or delay maintenance to save time and money in the short term, such decisions often result in higher long-term costs and operational disruptions.

The investment in preventative maintenance and responsible driving practices pays dividends in terms of extended truck lifespan, improved fuel efficiency, and enhanced safety. Moreover, it safeguards the reputation of your business and the livelihoods of those who depend on the reliable operation of your fleet.